I really wouldn’t call it a rocket, it’s more of a dart- a projectile launched with 100 effervescent tablets and some water. It does have a parachute I suppose, and an altimeter connected to a release mechanism. So at most, it’s a smart dart. According to Webster Dictionary a rocket “…can be propelled to a great height or distance by the combustion of its contents”. That last part is the key that makes me think it’s not really a rocket. I could be wrong, and in the greater scope it does not matter, I just thought I’d get that out of the way before I jump into the design.

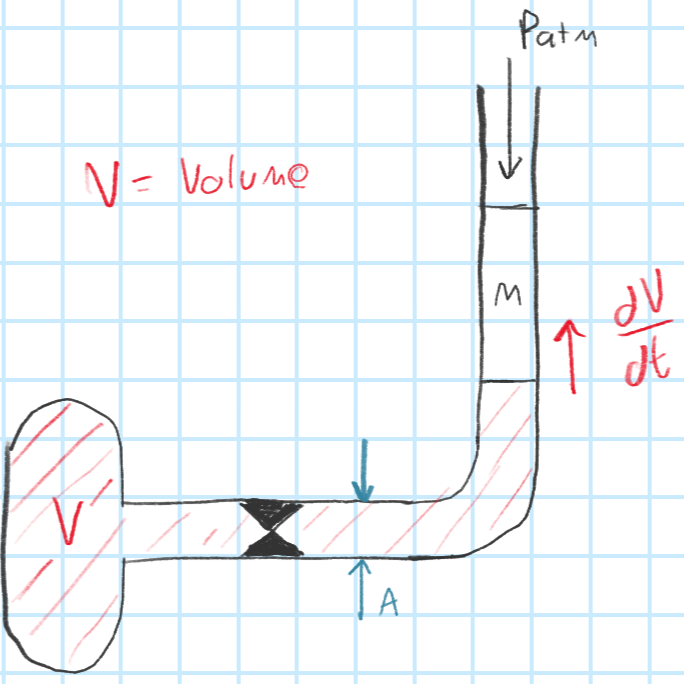

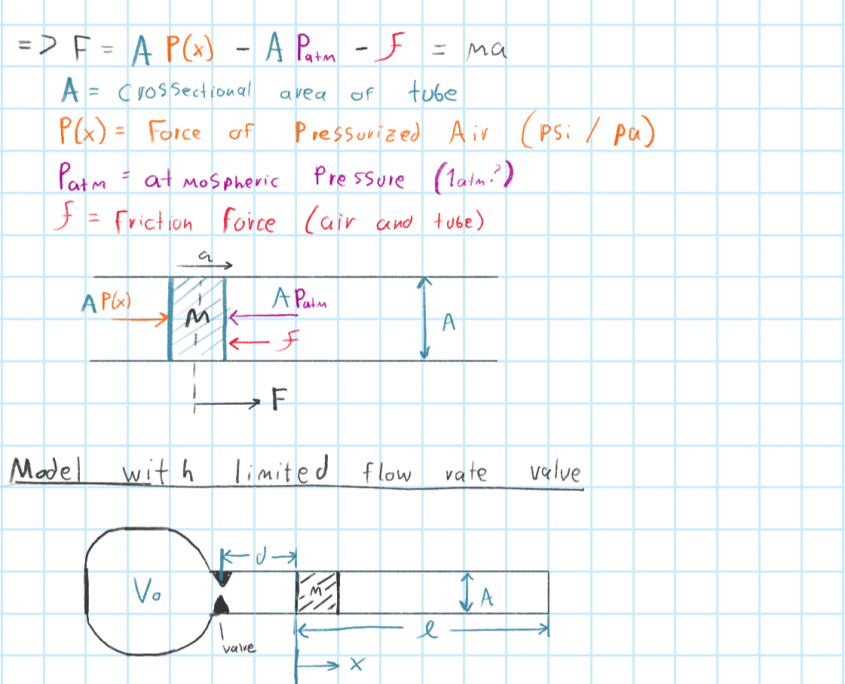

The launch system for the “rocket” bears striking resemblance to a potato canon. There is a pressure chamber that when released (or ignited to generate pressure in the case of a potato cannon), it accelerates the projectile out of the tube until reaching open air. At that point the projectile travels upward against gravity, until reaching a velocity of zero at apogee. Then begins its journey back down to the ground- deploying a parachute somewhere along the way for a safe landing.

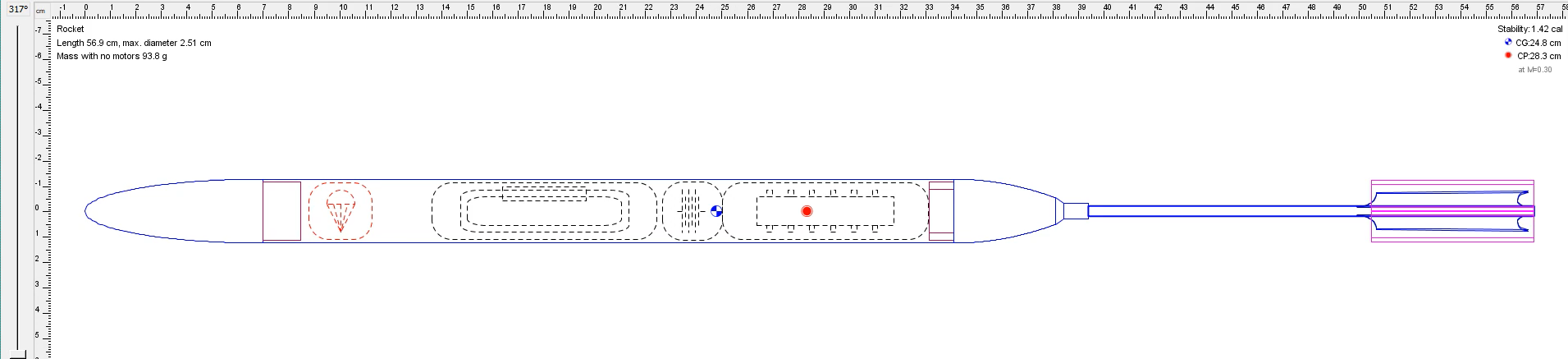

OpenRocket diagram of our design

Rough diagram of the launch system

Variable reference for modeling the launch system

The launch procedure begins by mixing 100 Alka-Seltzer tablets and some water in a chamber. The resulting reaction produces enough C02 to pressurize the chamber. This process has to be monitored closely as to not exceed the maximum pressure rating of the chamber, defined by the material properties and a safety factor. A key limitation in the competition is the pressure chamber cannot be made of any sort of metal. It can however, include metal components such as pressure release valves. The most widely available non-metal tubing is PVC, coming in (mostly) schedule-40 (lower pressure) and schedule-80 (higher pressure). With our very limited time constraint we were able to source some schedule-80 PVC, but not the necessary end caps and connectors to make the entire system high pressure. Since we weren’t prepared to dive into building our own reinforced chamber and then experimentally proving it’s ability, we settled for the lower pressure. This meant we had to double down on optimizing everything else: exit tube diameter, aerodynamics, projectile mass, and fluid (air) transfer efficiency. In the future we plan to develop our own pressure chamber capable of higher max pressure. We have seen other teams’ setups with what looks like carbon fiber, it’s strength in tension would make for a good pressure chamber reinforcement.

For now, the competition is in flux for the 2021 year. The 2020 competition was cancelled due to the Covid-19 pandemic. Next year (2021) will be the last chance to compete as our team graduates the following Spring. If and when it is confirmed I will hopefully be able to post more. For now you can always contact me with your thoughts or questions at info@braytonlarson.com.

Make sure to watch the entry video for an overview: